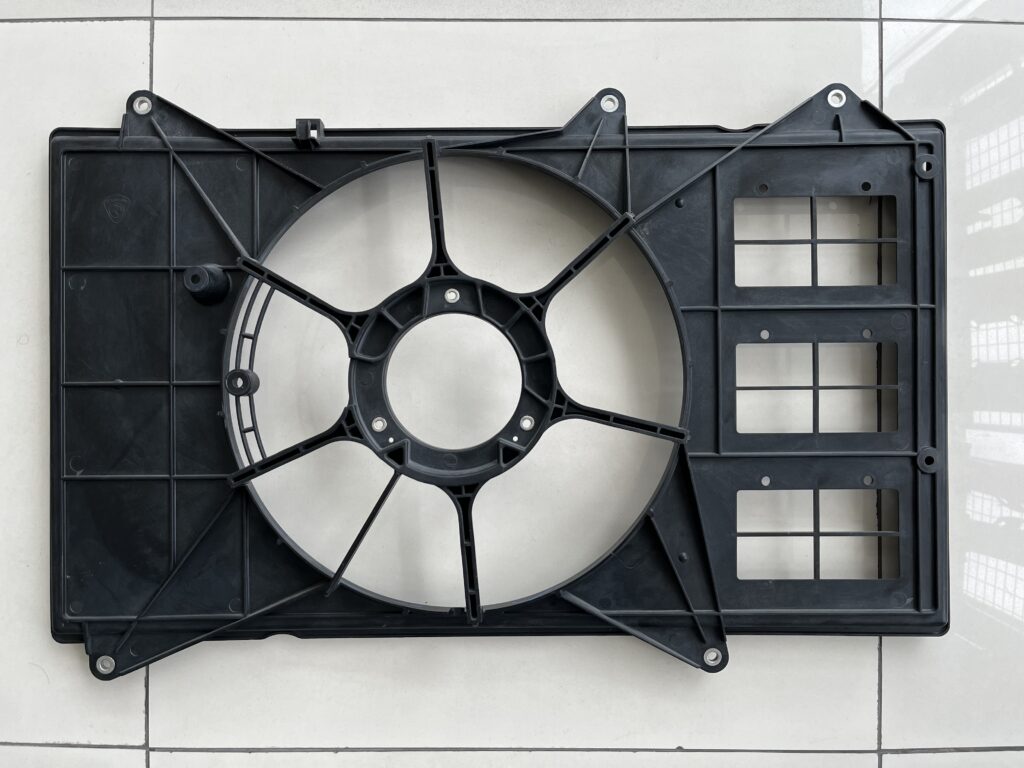

Insert Molding

Insert molding is defined as a variation of injection molding technique that involves the insertion of a metal part into a mold before the actual injection molding.

- Home

- Capabilities

- Insert Molding

Advantages of Sun High-Tech’s Insert Molding

At Sun High-Tech, insert molding is a core process that we use to create all kinds of products for our varied clientele base. Choosing to work with us opens you to a number of benefits, and some of these advantages including the following:

Reduced Assembly Costs

Our processes are the cheapest in the market, and you still get high-quality insert molds. We handle the entire process from inception to production at discounted prices as we understand businesses need some room to breathe once in a while.

Flexible Use of Material

We can work with all kinds of materials to bring your concepts to life. We have state-of-the-art machinery and a qualified working staff that know exactly what they are doing, and this ensures you get what you order.

Completion of Complex Parts

We can work with all kinds of materials to bring your concepts to life. We have state-of-the-art machinery and a qualified working staff that know exactly what they are doing, and this ensures you get what you order.

High-Efficiency

We have a team of qualified staff trained in all forms of the insert molding process. They will handle the product’s design and walk with you through the whole journey until the products are ready.