Mold Making

Sun High-Tech’s key expertise is our ability to create truly precise molds. Through our plastic injection mold making technology, you will be assured that your mold’s dimensions are perfect in every way.

- Home

- Capabilities

- Mold Making

Manufacturing Your Injection Molds From A To Z

Our injection mold making technology is capable of manufacturing a myriad of products. When you use injection mold making, you will be given top quality mold engineering, machining, and mold assembly. This versatility ensures that your products are as well-made as possible.

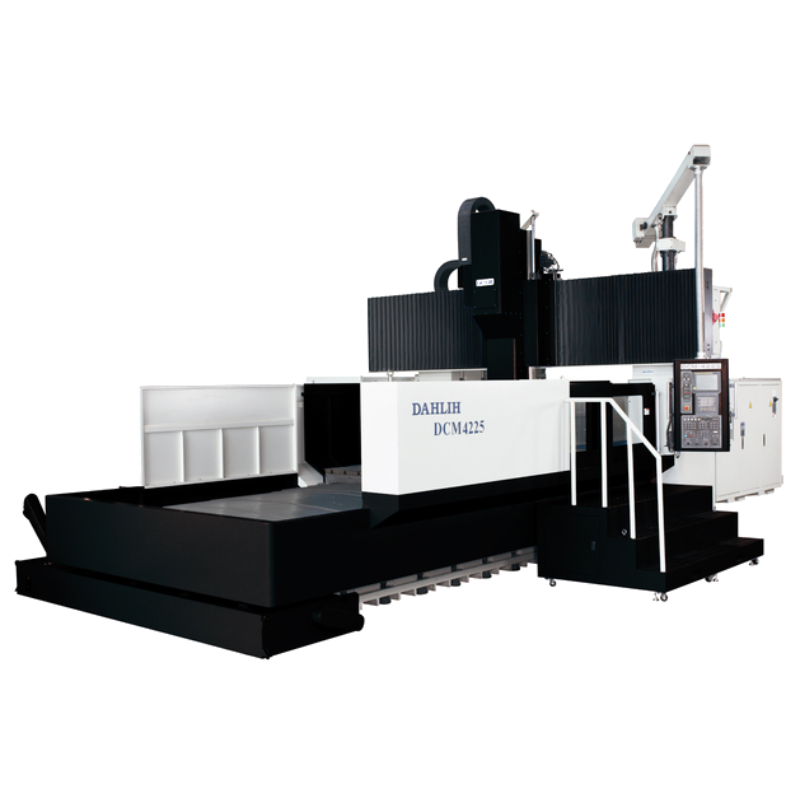

Advanced 5-Axis CNC Mold Making Technology Machine

One of our greatest advantages as a mold making company, is our injection mold factory. Not only is it manned by a highly trained crew of operators, but it is also equipped with various CNC machines, EDM machines, wire cutting machines, lathing machines, engraving machines, drilling machines and many more. These great examples of high-powered machinery allow us to fulfill all our client’s requests. Strict quality inspections will also be carried out during the machining process and product (mold) run-offs with final customer approval before deliveries.

Your Reliable Plastic Injection Mold Maker in Malaysia

Sun High-Tech thrives on the challenges of high-volume injection molding to produce quality parts at a mutually beneficial price. We give our customers added value through our flexible production options, durable, long-lasting molds, and expert insight. By setting our aim on creating the most reliable and efficient plastic molds possible, we can save customers even more time and money.

Steel - The First Step to Quality

The hardness of the steel utilized will directly affect the mold life. To make sure all Sun High-Tech molds meet the world class standard, we source steel from globally famous brands like ASSAB, Daido, Buderus and many more.

High Speed & Solid Accuracy in Every Mold

With the deployment of Cincinnati FTV 5-Axis and Haitian Double Column High-Speed CNC deep milling machines, with 20,000 Rpm, we can process edges or cooling gate that aren't straight to the same direction, thus manufacturing the exact mold to the exact injection molding part.

Both The Outside and The Inside Matter

At Sun High-Tech, we use multiple specialty machines to work the 'big thing' such as the outlook of our molds, and the 'small things' like rejector pin holes etc., Our equipment include:

CNC Machine

EDM Machine

Wire Cutting Machine

Drilling Machine

Lathing Machine

Engraving Machine

Gun Drilling Machine

Grinding Machine

Faro Arm Machine

Coordinate Measuring Machine

Quality Are Actually Assured

During each process of mold-making, coordinate measuring machine (CMM) is used to inspect dimensions. Only when the dimension of each part is confirmed will it enter the next step.

Only Real Product Speaks Enough

Sun High-Tech insists on running mold trails for each project in-house, making sure that our molds manufacture the exact product that our clients desire. During this period, we will communicate with you to confirm the product and modify it until the mold is perfect for you.